First Quality, Best Service. We provide not only the products, but also the SOLUTION.

-

Description

- Price Given on T/T Payment,Extra USD1000/Shipment For L/C Payment.

- Price Term: FOB Ningbo port, China.

- Payment: T/T( 30% deposit, 70% before delivery) or L/C.

- Lead Time: 30~50working days at sight the deposit.

- Packaging: Seaworthy Wooden Packing.

- After Sale Service:

Spare parts guarantee for one year,

2.Send technician for installation & training, the cost cover by buyer( round tickets, accommodation, an allowance of USD 100/day).

First Quality, Best Service. We provide not only the products, but also the SOLUTION.

Quotation

| Name: | Roll Paper Flexo Printing Machine | |||

| Model: | RY–850 | RY-950 | RY-1050 | |

| FOB

Price |

2-color | $28,000 | $31,000 | |

| 4-color | $34,000 | $37,000 | $50,000 | |

| 6-color | $40,000 | $44,000 | $60,000 | |

| Model: | RY-850 | RY-950 | RY-1050 | |

| Printing Color: | 1~6 color; | 1~6 color | 1~6 color | |

| Printing Speed: | Max. 120m/min; | Max. 120m/min; | Max. 120m/min; | |

| Max. Paper Reel Width:

|

850mm; | 950mm; | 1050mm | |

| Max. Printing Width:

|

830mm; | 930mm; | 1020mm | |

| Max. Unwinding/Rewinding

Diameter: / |

Φ1400mm; | Φ1400mm; | Φ1400mm; | |

| Printing Girth: | 180~420mm; | 180~420mm; | 180~420mm; | |

| Precision of Chromatography:

|

±0.15mm; | ±0.15mm; | ±0.15mm; | |

| Plate Thickness: | 1.7mm | 1.7mm | 1.7mm | |

| Paste plate tape thickness:

|

0.38mm | 0.38mm | 0.38mm | |

| Main Motor power: | 7.5KW | 7.5KW | 7.5KW | |

| Total Power: | 25KW; | 30KW; | 30KW | |

| Power Source | 380V 3-phase, 50Hz | |||

| Dimensions(L*W*H): | 3500*1850*2200mm; | 3500*1950*2200mm; | ||

| Machine Weight: | About 3800KG; | About 5000KG; | About 5500KG | |

Video Link:

https://www.youtube.com/watch?v=kSzYDet2D7g&list=PLjB-v2tkpOHeL-sopfBkZrNlnMmxy5gfo

Remarks:

- Price Given on T/T Payment,Extra USD1000/Shipment For L/C Payment.

- Price Term: FOB Ningbo port, China.

- Payment: T/T( 30% deposit, 70% before delivery) or L/C.

- Lead Time: 30~50working days at sight the deposit.

- Packaging: Seaworthy Wooden Packing.

- After Sale Service:

Spare parts guarantee for one year,

2.Send technician for installation & training, the cost cover by buyer( round tickets, accommodation, an allowance of USD 100/day).

Parts Cost:

| Ceramic Anilox Roller : | $1050/pc |

| Print Cylinder (diameter 160~420mm): | $150/pc |

| Double-side Adhesive Tape: | $550/roller (about 24m) |

| Squeegee Blade: | $290/pc, |

| Corona: | $3500/pc |

| UV system Include:

one print unit (ceramic anilox roller + rubber roller) 2 set ultraviolet radiator dryer (must need 2 sets dryer to ensure speed), also include IR dryer, (can print the 5th color, can use water varnish ink) |

$18500

|

Flexo Roll Paper Printing Machine

Description:

- Adopt the Ceramic Anilox Rollerto press

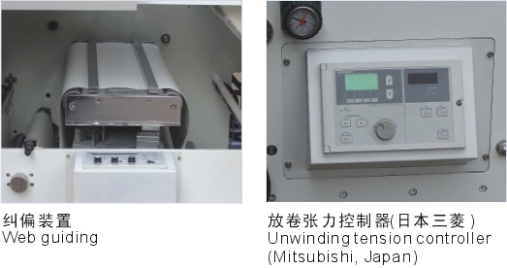

- Unwinding and rewinding are controlled by magnetic power brake, clutch, (Optional:automatic tension controller of mitsubishi, made in Japan).

、、() - Each printing unit adopt 360ofor registration.

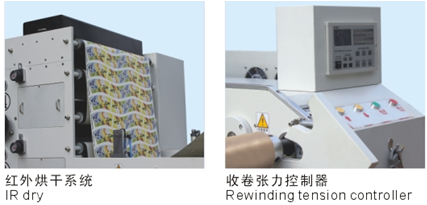

360 - Each printing unit have one IR(infrared) d

- While parking, the RUBBER roller automatically depart, and keep slowly running, to avoid the ink become dry.

,, - Adopt imported step-less AC-driver(transformer, converter) to control the main motor.

- With the function of the procedure: unwinding, web guiding, corona discharging,printing, IR drying and rewinding can be finished in whole flow.It is an ideal machine to print many kinds of paper (cup paper, label paper, etc).

、、、、、, - Option: Varnishing Print (gloss print), UV Print unit is available on user order. (Each UV print unit USD14000)

- Option: Corona treatment, (this device good for double PE paper)

Parts Equiped with the machine

Rewinding / Unwinding separately in two side. ($2000 extra)

Basic Configuration

| 1) One set of Feed roll unit 1 |

| • Max Feeding Width 1400mm

• One 3inch air swelling shaft can change 6inch air swelling shaft • Auto tension control system of unwinding and rewinding, one Magnetic powder brake ( Mitsubishi Japanese). • Fast inflating gun • 1400mm • 316 • ,、()1,()1 • |

| 2) One set of EPC control system 1 |

| • One set of Paper binding table

• The paper guide roller adopts high hardness anodized • Adopt the ball screw electric actuators • Adopt rectifying photoelectric head to rectify induction • Electronic paper web guide traction device, there was a small offset paper web movement, the system can accurately continuously revised • Closed-loop control system • Test method: edge • Rectification precision:±0.12mm • 1 • • • • ,, • • : • :±0.12mm |

| 3) One set of Adjustable feeding paper system (Dual pressure roller)

()1 |

| • Dual pressure roller pressure feeding together

• Printing paper tension adjusted • • |

| 4) Four Color printing unit (just sample for 4-color) 4 |

| • The printing unit adopt 45 degrees of DP13 helical gear structure

• Reserved image detection station • Net roller, version roller pressure pneumatic clutch • Ceramic net cable roller (as require) • Plate cylinder 4pc .(as require) • Manual transverse focusing alignment 4 set • Manual vertical focusing alignment 4 set • Single pole reverse scraping system 4set • Stainless steel cartridge 4set • Fast changing plate cylinder without any tools • Net roller rotation function: every time when stop network roll automatically, prevent ink roller surface dry solid, the network cause net hole plug. • 4 cylinder gears:cp1/8 • 45DP13。 • • 、 • 4,() • 8.() • 4 • 4 • 4 • 4, • , • :,,。 • 4:cp1/8 |

| 5)Dryer (one set) 1 |

| Infrared heating drying printing unit,IR Driver 4set (each color unit one)

, 4 |

| 6) One set of the rear paper tension system1 |

| 7) one set rewinding system1 |

| • A set of winding for rewinding after printing, with One 3inch air swelling shaft can change 6inch air swelling shaft

• Max rewinding diameter 1400mm • ,3,6 • 1400mm |

| 8) Installed version machine (one set) |

| • On the ordinary version machine, including bilateral symmetry points and 10 times the magnifying glass

• For version, in order to achieve multi-color overprint accurately • Used for products with quick replacement products • ,10 • , • |

| 9) One tool box |

| Electric parts | ||||

| Name | Brand | |||

| 1 | Converter | Schneider | ||

| 2 | Rewinding Converter | Schneider | ||

| 3 | Rewinding PLC | Panasonic | PLC | |

| 4 | Temperature control | China | ||

| 5 | EPC control system | |||

| 6 | Auto tension controller | Unwinding, Mitsubishi

Rewinding, Chuying |

,

|

|

| 7 | Intermediate relay | Omron | ||

| 8 | Breaker | China CHNT | LG | |

| 9 | Solid Relay | UK, Kudeng | ||

| 10 | Contactor | Schneider | ||

| 11 | Control button | Schneider | ||

| 12 | Pneumatic control and

Pneumatic components |

AIRTAC | ||

| 13 | Ceramic anilox roller | Shanghai | ||

| 14 | Magnetic powder clutch | ChinaFZ100K | 10K | |

| 15 | Meter coun ter | |||

| 16 | Host | 5.5KW | 5.5KW | |

| 17 | Rewinding motor | 2.2KW | 2.2KW | |

| 18 | Installed version machine | By ourself | 1 | |

Spare Parts List

| Description | Model | Quantity | |||

| 1 | IR Lamp | 9pcs | |||

| 2 | Button | Green | 2pcs | ||

| 3 | Button | Black | 2pcs | ||

| 4 | a . c . contactor | 1pcs | |||

| 5 | straight-through joint | APU 6 | APU 6 | 2pcs | |

| 6 | straight-through joint | APU 8 | APU 8 | 2pcs | |

| 7 | pressure -regulator vavle | SR200-08

(、) |

SR200-08

(、) |

1pcs | |

| 8 | Solenoid valve | 220V 4V210-08-DC220V | 220V 4V210-08-DC220V | 1pcs |

Video Link:

https://www.youtube.com/watch?v=kSzYDet2D7g&list=PLjB-v2tkpOHeL-sopfBkZrNlnMmxy5gfo

Machine Video

Machine Video