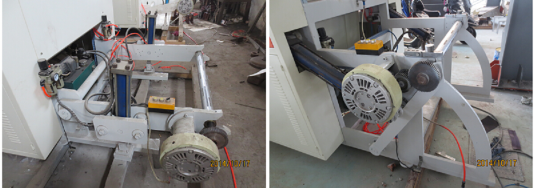

QC950 Automatic Roller Dutting & Creasing Machine

-

Description

Remarks:

- Price Term: FOB NINGBO PORT, CHINA

- Payment: T/T (30% for deposit,70% before delivery) or L/C.

- Load time:20 working days at sight the deposit.

- Packaging: Wooden packing applies to export

- After sale service:

- Spareparts guarantee for one year in machine arrival.

QC950 Automatic Roller Dutting & Creasing Machine

QUOTATION

| NO. | Goods Description | Quantity | FOB Unit Price |

| 1 | QC-950 automatic roll die-cutting & creasing machine | 1 | $ 35000 |

| 2 |

Remarks:

- Price Term: FOB NINGBO PORT, CHINA

- Payment: T/T (30% for deposit,70% before delivery) or L/C.

- Load time:20 working days at sight the deposit.

- Packaging: Wooden packing applies to export

- After sale service:

- Spareparts guarantee for one year in machine arrival.

2.Send the technician for installation & training. Buyer bears the cost (round tickets, accommodation, and allowance of 120 USD per day).

QC-950/1200(),,。、、、、,、、、。、、、、、、、、、,、、、。、,、、、。

QC-950/1200 is an ideal and professional machine in die-cutting,creasing,embossing and full-stripping various PE coated paper, normal paper, corrugating paper and plastic material. It applies to paper cup, paper box, medical package, wine package, food package and other environmental protection products. It adopts micro-computer, HMI, servo positioning, alternating current frequency converter, automatic counting, photoelectric rectifying, and pneumatic lock cutting plate, electromagnetic clutch, centralized oil lubrication, overload protection and distinctive gearing. All of these is the guarantee of steady pressure, precise positioning, smooth running, safety and reliability operation.

Technical Specification

| Type | QC-950 | QC-1200 |

| Paper Convey Width: | 250mm-900mm | 250mm-1200mm |

| Max Roll paper diameter | 1800mm | |

| Cut Precision: | ± 0.10mm | |

| Production capacity | 150-210/times/min | 150-210/times/min |

| Maximum cutting size: | 950 x540mm

950 x640mm(optional) |

1200 x650mm

1200 x750mm(optional) |

| Sui Material: |

120-600g/m2 white cardboard, PE coated paper, Kraft paper.etc | |

| Maximum Pressure: | 350T | |

| Power: | 14.5KW | |

| Total Weight: | 6.2T(standard);

|

8.5T(standard)

10T (heavy duty) |

| Overall Dimension: | 4200 x 2100 x 1850 mm | 4400 x 2300 x 1850 mm |

| Working Air Source: | Air pressure: 0.6Mpa; | |

| Working air: 0.3m³/min; | ||

| other size can be customized. | ||

Main Feature:

1.The working speed is 150-210 times per minute,the level of the capacity in China is 120times per minute. It has the ability to die-cutting, creasing and embossing for various shapes.150-210 /,120/;、、、、。

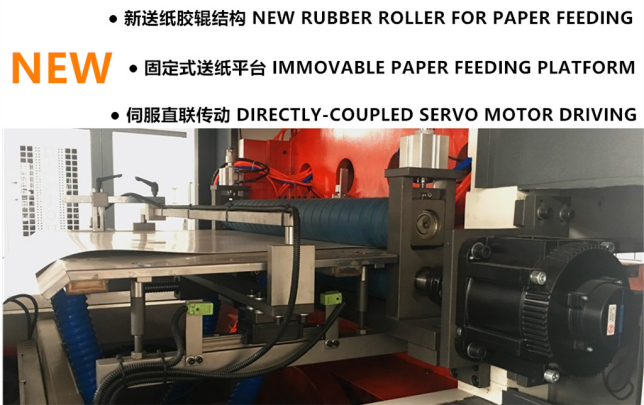

- Paperconveyed by servo motor to ensures steady and accurate conveying. photoelectricity sensorchecks the color code of printing to ensure fix the paper position accurately.,;,。

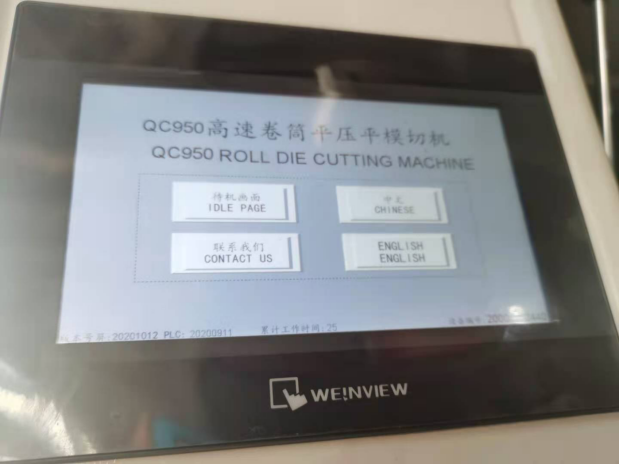

- Electriccontrol system uses PLC and HMI. Equipped with safety refinementsto make acoustic – optical alarming and auto stop when some faults.PLCHMI,,。

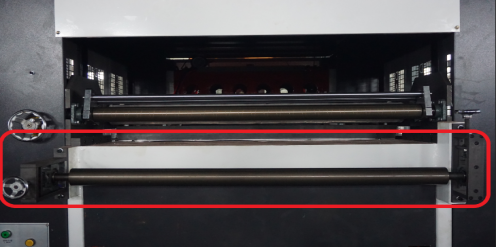

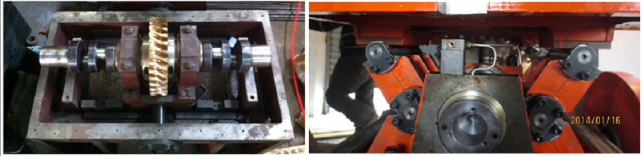

- Wormwheel and worm transmissionsystem ensures the powerful and steady pressure;It is very convenient and accurate to adjust pressure through HMI. ,,;,、。

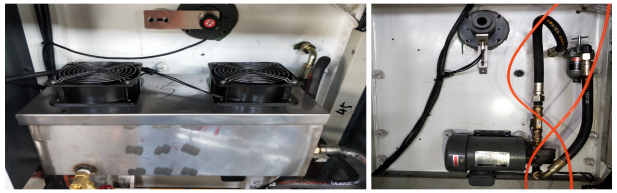

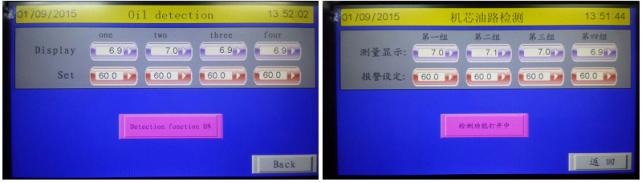

5.Lubricating with oil circulation and alarming when lack of oil to ensure smooth running and prolong the machine life.,,,。]

- The die-cutting frame uses pneumatic locking system to convenient operation. Die-cutting down steel board from Taiwan is accurate and lasts forever.,,,。

7.It adapts electric control pneumatic clutch to protect the machine when start and emergency stop..The flywheel provides a mounting location to the clutch and also can increase the pressure.,;,。

Advantage and improvement:

- Machine Host. New design: Worm and Worm wheel together with crankshaft same as the sheet die-cutting machine. The previous design: off-center shaft.

QC-950/1200,,,。

The New Design The Previous Design

- Pressure Adjusted. New design: The pressure is automatic adjusted through the motor to control the four feet by HMI.And the pressure can be shown in the HMI.It is very convenient and accurate. The previous design: manual adjusted through gear wheel or the screw.

QC-950/1200,,,、、;

The New Design The Previous Design

- Positioningblock in movable platform we add one more positioning block in movable platform. It makes the pressure of the platform more stable, and endurable.

,,。

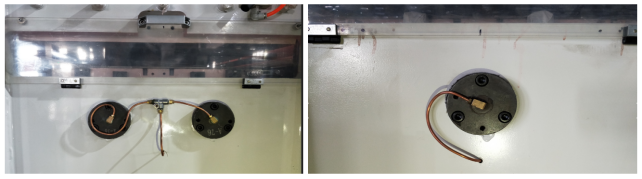

- Oil circuit. New design: The outside oil circuit adds a filter to clear the oil and a flow switch to monitor lacking oil. The previous oil circuit is crude and confused.(the first machinery equips with alarming of oil lacked)

QC-950/1200,(),,。

The New Design The Previous Design

- The main driving parts in host is protected by the lubrication system. If the data shows problem, the machine will stop and alarming. Then you must check the driving parts,,,。

The New Design

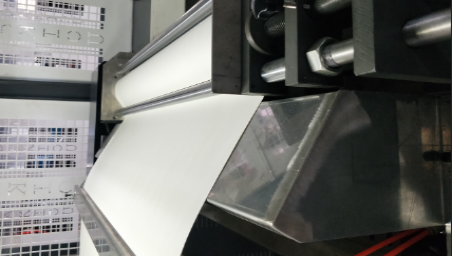

- Air cylinder paper pressure system. In front of the paper feeding platform, we add the air cylinder paper pressure system to ensure the paper convey more smoothly and quickly. We are the first one and the only one machinery who adds this system,,。

- PLC program:The new design: We make two PLC program to fit for the different quality of printing. Be more functional and accurate,、,。

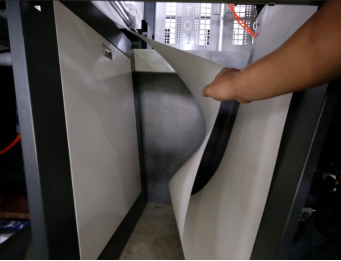

- Paper feeding balance regulatoradd new type paper feeding balance regulator to adjust he minor unbalance situation.

,。

- Paper damper. In order to avoid the paper shaking, we add one more damper to make the paper tractable. The paper leech on the damper when machine is running. So we can feed paper more stable and faster

,,。,。

- Roll Paper Loading: The new design: the hydraulic cylinder pushes downward, so it is stronger than the previous design.

QC-950/1200,,、。

The New Design The Previous Design

- Paper blocked alarm system. The new design adds the alarm system to make the machine stop when paper feeding blocked.

QC-950/1200,,,,。

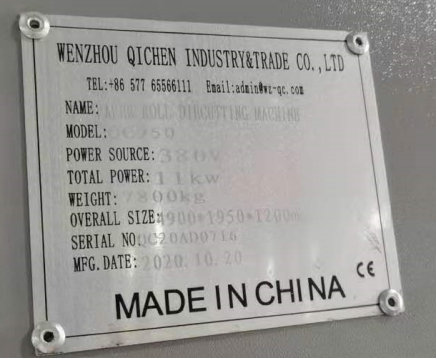

NAME PLATE IN THE MACHINE

Components Brand:

,。

- If different width, we can do it according to your requirement.

Spare parts & tools

| Tool box

1 pcs |

1 pcs

|

1 set |

1pcs |

| screw 1set | |||

|

air pipe |

|||

, 1set |

1pcs |

1pcs |

1 set |

1pcs |

5 5pcs |

1 1pcs |

55pcs |

| 8*50 55pcs 6*20 2pcs | 8*30 55pcs | 1 1set |

| Maintenance manual | |||

| ,:

change or add if necessary |

1month | 1senson | 1year |

| lubracation oil | √ | ||

| oil pump | √ | ||

| sensors | √ | ||

| motors | √ | ||

| (、)

electric and cylinder |

√ | ||

| pressure adjustment | √ | ||

| sealing system | √ | ||

| tension system | √ | ||

| hydraulic | √ | ||

| shaft unwiding | √ | ||

| vacuum feeding | √ | ||

| cutting steel board | √ | ||

| convey belt | √ | ||

| clear: | |||

| oil pipe | √ | ||

| sponge of leak proof | √ | ||

| filter | √ | ||

| rubber roller | √ | ||

| other parts | √ | ||

| ,

If abnormal noise or unknown fault,please contact with manufacturer immediately. |

|||

Machine Video

Machine Video