ZBJ-OC12 Ultrasonic Open Cam Paper Cup Machine

-

Description

ZBJ-OC12 Open Cam Paper Cup Machine improved on our hot sale ZBJ-X12 model machine,With advanced design and intelligent program, more reliable and durable, competitive price.It makes both one-side or two-side PE-film-coated paper cups after running a whole procedure of automatic Multi-step pre-printed-cup-fan-paper Feeding (Multi-step paper-feed and Anti-back device to keep the accurate position), cup-body-side welding, silicone-oil lubricating(for top curling), robot transfer cup body, bottom-disk punching, bottom pre-heating and pre-folding, main heating, bottom knurling(cool device for 2PE), top curling, cup discharging and collecting.

First Quality, Best Service. We provide not only the products, but also the SOLUTION.

Quotation

style=”height: 857px;” width=”730″>

| HS Code: | 8441309000 | ||

| Name: | Open Cam Paper Cup Machine | ||

| Model: | ZBJ-OC12 Heater | ZBJ-OC12 Ultrasonic | |

| FOB Ningbo/Shanghai | $16,000/set | $17,000/set | |

| Cup Bottom Same &

Cup-Angle Same |

$400

(Half Set Mold) |

$400

(Half Set Mold) |

|

| Cup Bottom different, or Cup-Angle different | $800

(Whole Set Mold) |

$800

(Whole Set Mold) |

|

| Option: Safety Fence (prevent worker hand into machine, better look,) Extra $500 | |||

| Model | ZBJ-OC12 Heater | ZBJ-OC12 Ultrasonic | |

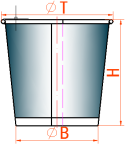

| Paper Cup Size: | 40ml ~ 300ml | 3 ~ 16 oz | |

| Rated Speed: | 70 ~ 8 PCS/minute (depend on cup size, speed different)

Speed affected by cup size, paper quality & thickness |

||

| Raw Material: | One side PE Coated Paper | One-side or Two side PE coated paper | |

| Suitable paper weight: | 140~250gsm | 180~350gsm | |

| Power Source: | 50Hz, (380V 3-phase, 50Hz), (Better use 380V 3-phase)

* if User power different? Please INFO US IN ADVANCE. |

||

| Total Power: | 8KW | 9KW | 15KW |

| Working Power: | 3.5 KW | 4 KW (compressor hot air) | 13.5KW Blower- hot air |

| Total Weight: | GW/NW: 2200/2100KG | ||

| Pack Size (L*W*H) | 2250 x 1340 x 1950 mm | ||

| Working Air Source: | Air pressure:0.4Mpa; Air Out-put:0.6m³/minute

User should BUY Air Compressor |

||

| Cup Side Welding: | Pre-heating + Heater | Ultrasonic | |

| Cup Bottom Heating: | Heater (40ml~100ml) | Hot Air (Need Air compressor supply air)

Or Self Hot Air (blower hot air) |

|

| Hot Air (100ml~12oz) | |||

| Cup Bottom Knurling: | Heater | Heater Knurling (if use single PE coated paper) | |

| Cool Device (circle water), for double PE coated paper | |||

| We Reserve the right to alter specifications without prior notice. | |||

Remarks:

| Price Item: | FOB, Ningbo. | |||

| Payment

Item: |

Option 1, T/T payment (30% deposit, 70% before delivery).

Option 2, Irrevocable L/C at sight (If pay by L/C, Extra $1000 bank charge per shipment). **** The buy is welcomed to test machine before delivery. |

|||

| Delivery Time: | About 50-60 days after receuve the deposit (actual delivery time given while order confirm) | |||

| Package: | Standard export package. (need special package, please info us in advance). | |||

| Electric Power Source: | The electric power source for this machine adopt 380V 3-phase 50Hz.

If the buyer’s power source different, should declare in advance. |

|||

| After Sales Service: | ||||

| 1 | We offer a 12 months warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems. All failures/breaking caused by improper operation of the buyer and/or normal abrasion are not within the warranty. | |||

| 2 | Spare Parts: Each machine has its standard spare parts (see list). | |||

| 3 | Manual, Video, to help operate machine, Questions response within 48 hours (except holiday). | |||

| 4 | The buyer come to learn how to operate machine, how to adjust, how to change parts. It is free.

(buyer should pay for his cost of ticket, hotel, food, etc). |

|||

| 5 | The seller agrees to dispatch technician for installation & training, the cost covered by the buyer.

Technician cost includes: round tickets, accommodation (hotel, food), an allowance of USD100 a day. |

|||

Main improved:

- Speed 70~90 cup/minute

- HMI & PLC Program computer control, easy operate, fault auto-stop and easy solution.

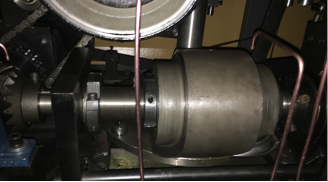

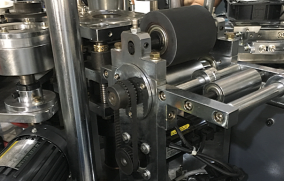

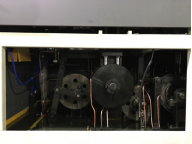

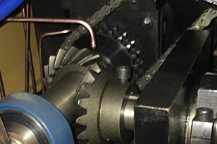

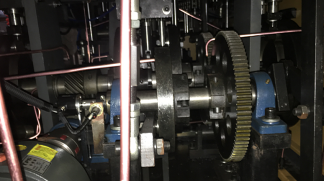

- Adopt Open Cam(8-divide) for the dividing moving, compare with index gear box, easy maintenance, stable and reliable, easy replace broken parts.

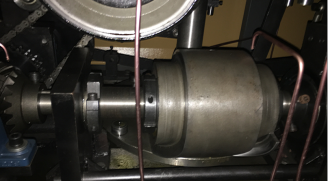

- Main mechanism and movement control by quality gears and shaft/axis, which is more efficient than chain axis.

- Only ONE main turntable, more efficient and reliable.

- Self lubricate (automatic oil lubricate),

- 11 sensors detect all steps, any fault auto stop,

- Quality bearing and electronic element, long life,

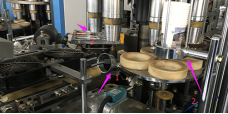

- Robot straight lift the cup body to main mold.

- Steppermotor control the bottom feed, precision and reliable.

- Bottom disk straight punched and send to the cup body, less wastage and precision.

- Separately cam control the bottom movement, machine smooth and light,

- Advanced bottom knurling system, reliable and long life,

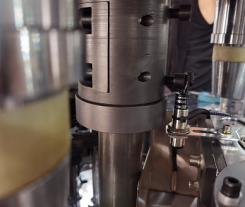

- Cup side sealing ultrasonic (1PE & 2PE paper),

- Bottom hot air heating , good sealing,

- Working power less, save cost,

- With cup collector/stacker, One worker run 2~3 sets cup machine, save labour,

- Optimize the movement design, frame, parts, machine more light pressure, long life time.

Description:

ZBJ-OC12 Open Cam Paper Cup Machine improved on our hot sale ZBJ-X12 model machine,With advanced design and intelligent program, more reliable and durable, competitive price.It makes both one-side or two-side PE-film-coated paper cups after running a whole procedure of automatic Multi-step pre-printed-cup-fan-paper Feeding (Multi-step paper-feed and Anti-back device to keep the accurate position), cup-body-side welding, silicone-oil lubricating(for top curling), robot transfer cup body, bottom-disk punching, bottom pre-heating and pre-folding, main heating, bottom knurling(cool device for 2PE), top curling, cup discharging and collecting.

Sensors:

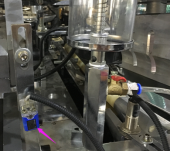

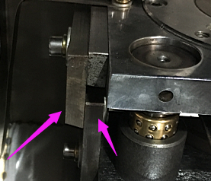

| Sensor 1, Cup fan shot sensor (fan short alarm) | Sensor 2, Cup fan come detect sensor

Send signal to ultrasonic, prepare work |

| Sensor 3, Ultrasonic work sensor,

Cup fan pass, sensor 2 work, sensor 3 approach Then ultrasonic work, |

Sensor 4, Cup body sealing sensor

No sealing, alarm and stop, |

| Sensor 5, Cup body transfer sensor

Only detect cup body on mold, bottom feed and punch

|

Sensor 6, bottom disc punch sensor, No bottom, Sop

Sensor 5 work, Bottom feed and disc punched,

|

| Sensor 7, Cup bottom pull sensor,

Bottom reel feed short, auto pull. |

Sensor 8, Cup drop sensor

Cup drop in knurling, curling furnace, stop, |

| Sensor 9 Machine position sensor

Control the motor stop position. |

Sensor 10 count sensor,

Counter sensor on collector/stacker, (if no need collector, no counter sensor). |

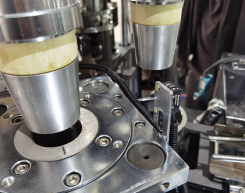

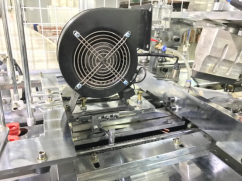

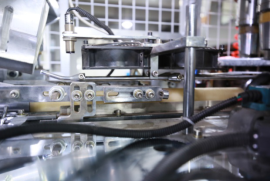

Parts of the machine

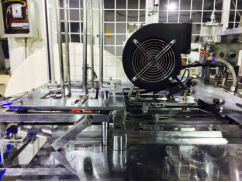

| Blower to cool the Ultrasonic System | Fan cool the cup body (after ultrasonic sealing) | ||

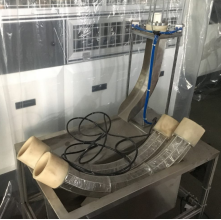

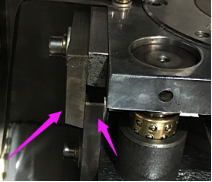

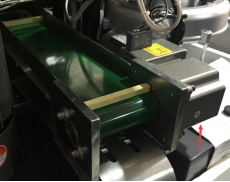

| Long distance paper feeding, guide the paper to right position. | |||

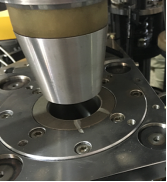

| Bottom directly feed to cup cone,

Easy control and more precession , |

Air gun, Blow the paper edge, rust,

Help to clean the machine |

Bottom edge cut knife,

Cut bottom edge to pieces. |

|

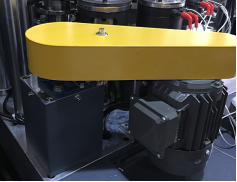

| Motor: 6motors | ||

| Main motor | Pump, Oil lubricate pump | Knurling Motor |

| Bottom pull motor (pull heavy roller) | Bottom Feed Stepper motor (one cup one bottom) | |

| Bottom edge transfer belt motor

Transfer the edge cut pieces out . |

Bottom edge cut knife,

Cut bottom edge to pieces. |

|

|

3, Bottom punch disk straight to cup cone body. 2, Cup collector (can change to blower to stacker) |

Quality Electronic List

Quality electronic  Plant

Plant

Pack & Delivery

Pack & Delivery

20 Feet container load 4sets of OC12,40 Feet container load 8sets of OC12

Running Machine Video Link: https://youtu.be/U5R-o8Xr2ksRunning at our customer’s factory: https://youtu.be/-STo2RXG5pM

Machine Video

Machine Video