Technical Specification:

| Model | WT-A30 Ultrasonic Paper Cup/Bowl Sleeve Machine |

| Paper Bowl Size | 20 oz-50 oz (mold exchangeable) height up to 125 mm |

| Raw Material | 170-450 g/㎡PE paper, varnishing printed paper, or other film coated paper (can be sealed by ultrasonic) |

| Rated Productivity | 40-50 pieces/minute; |

| Power Source | 220V/380V/ 50Hz or other required |

| Total Power | 4 KW |

| Total Weight | 1000KG |

| Package Size(L x W x H) | 2450 x1200 x2000mm; |

| Working Air Source | 0.6Mpa, Air Out-put:0.3 m3/minute |

| Available to make machine against your requirement. | |

The part we used VS normal one:

1) We use 125 type gear box, which has two years warranty.

Normally, 100 type gear box is used.

* 125 type is much bigger and stronger than 100 type.

* 100 type gear box, if used for one year, is easier to have problem.

2) We use 1:30 100 type Speed reducer

Normally 1:20 80 type speed reducer is used.

* 1:30 100 type speed reducer is more stable than 1:20 80 type speed reducer.

The speed reducer and the gear box are very important to the machine. They control the whole machine, if there are some problems with these two parts, then, you have to change the gear box and speed reducer. In this case, the machine should be taken apart, because they are inside the machine. It takes much time, and sometimes you cannot install the machine correctly. So it is necessary to use better gear box and speed reducer.

3) We use 3 Cam to control the folding process.

Normally 1 Cam is used to control the folding process.

* Each Cam control each arm, folding process is more accurate and easy to adjust.

4.We use two times paper feeding process.

Normally one time paper feeding process is used.

* Two time feeder make feeding and folding has more time to done process.

* Paper fan not easy corrugated when fan goes folding process.

5.We use multilayer suckers for the paper taking

Normally single sucker is used.

* Multilayer sucker is much powerful and make the process successful.

* Multilayer sucker has long life; when the top is wornout, just cut the top.

Free Accessories List:

| Number | Name and description | Quantity | Note |

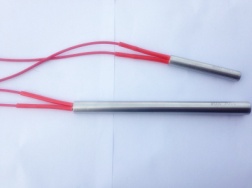

| 1 | Electric heater punching bottom (Short) | 1pc |  |

| 2 | Copper Immersion Heater (Long) | 1 pc | |

| 3 | Spanner | 1pc |  |

| 4 | Big spring | 1 pc |  |

| 5 | small spring | 3pcs | |

| 6 | Bottom knurling heater | 1 pc |  |

| 7 | Pre-heater | 2 pc |  |

| 8 | bearing(5204) + Knurling wheel | 1 set | |

| 9 | inner hexagonal spanner | 1 set |  |

| 10 | outer hexagonal spanner | 1 set |  |

| 11 | bottom screw M16 | 6 pcs | |

| 12 | oil gun | 1 pc |  |

| 13 | Neon-electroscope | 1 pc |  |

| 14 | Screw driver | 1 pc |  |

| 15 | Hammer | 1 pc |  |

| 16 | Machine spanner | 1 pc |  |

| 17 | Makintosh |  |

|

| 18 | Box spanner 12-14 17-19 |  |

|

| 19 | Pincers | 1 pc |  |

| 20 | Rubber of silica gel (Red 3pcs , white 2pcs ) | 5 pcs |  |

| 21 | Hexagonal screw 6,8,10,12 — each 2pcs | 8 pcs |  |

| 22 | flat shim D12-D16、12 Nut | 10 pcs |  |

| 23 | operation manual | 1 pc |  |

| 24 | instruction of inverter | 1 pc |  |

Machine Video

Machine Video